Media coverage

Sudden! The world's largest MLCC factory is discontinued! Samsung discontinues production by 1/4! The price increase may continue!

Create_time:2020-04-09 Views:480

The impact of the COVID-19 on the supply chain is gradually emerging.

The world's largest MLCC factory is discontinued!

The latest news is that MLCC (Multilayer Ceramic Capacitor) manufacturer Murata has ceased production at its factory in Fukui, Japan. Previously, Murata's factory in the Philippines had ceased production.

MLCC is known as the "rice of the electronic industry". According to public data, the global MLCC market size in 2018 was approximately 11.4 billion US dollars, with downstream industries distributed as 38% for mobile phones, 19% for PCs and peripherals, 16% for automobiles, 15% for audio and video IOTs, and 12% for industrial control and others.

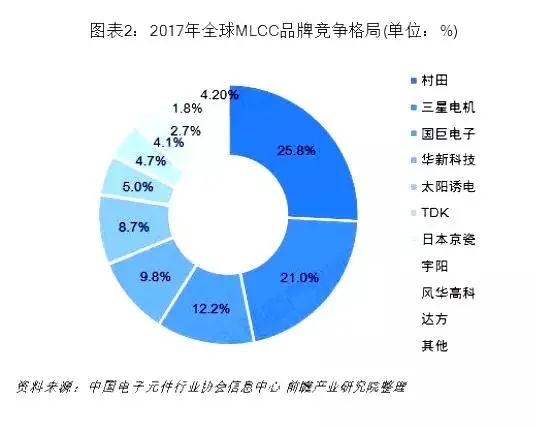

Murata is the world's largest MLCC manufacturer, with a global market share of over 25%. Overall, Murata, Samsung, Guoju, Huaxinke, and Taiyin account for nearly 80% of the total market share.

Due to the impact of the epidemic, Murata has been in a state of insufficient construction and low capacity utilization since February.

Samsung discontinues production by 1/4! Parts supply is disconnected!

The latest news is that in response to the COVID-19, the Japanese government plans to issue a declaration of emergency in seven regions, including Tokyo, Kanagawa Prefecture, Saitama Prefecture, Chiba Prefecture, Osaka Prefecture, Hyogo Prefecture and Fukuoka Prefecture.

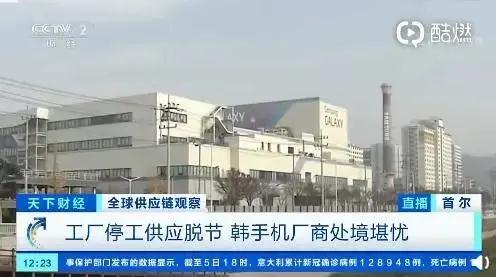

According to CCTV Finance, as the epidemic continues to spread globally, South Korean mobile phone manufacturing companies are facing multiple pressures such as factory shutdowns, disjointed component supply, dealer closures, and shrinking market demand. Samsung Electronics, the leading enterprise in the South Korean mobile phone industry, is the only smartphone factory located in South Korea. Last month, there were multiple confirmed cases, resulting in the closure of the work floors where relevant personnel are located and the suspension of some production lines.

Currently, one quarter of Samsung Electronics' 37 production lines worldwide are in a state of shutdown, including Samsung Electronics' largest smartphone factory in India.

Nichicon employees have been infected one after another! Returning to work has become a fan!

Nichicon was also forced to shut down due to its employees being infected with the epidemic. On April 1st, 3rd, and 6th, the company released three press releases regarding the infection of employees at Nichicon Kusatsu Co., Ltd., but the situation was not very optimistic.

It is understood that the Nichicon Caojin factory mainly produces capacitors for power/machinery, thin film capacitors for electric vehicles (EVs), and other products.

The first infected employee was a male in his 60s who was sent to the hospital after showing fever symptoms on March 27. On March 31, the employee received nucleic acid test for novel coronavirus, and the result was positive.

In order to avoid further spread of the epidemic, the Nichicon Caozin factory was temporarily suspended from April 3-16. The company stated that it will continue to monitor the health status of employees who have had close contact with infected employees.

On the 6th, Nichicon released a press release reporting the latest epidemic situation. According to the press release of this epidemic, since the factory announced its closure, 8 employees have been found positive in the nucleic acid test of novel coronavirus.

Among them, 4 people were discovered on the 3rd, 3 people were discovered on the 4th, and 1 person was discovered on the 5th. At present, these employees have been sent to the hospital, and the factory involved will still be closed before April 16th.

Supply and demand are tightening! The industry reshuffle is here!

Due to the impact of the epidemic, passive component manufacturers have started construction later this year than in previous years, and their shipping plans have been postponed, leading to further tension between supply and demand. At the beginning of this year, Guoju and Huaxinke both raised prices for some products.

What will be the impact on the MLCC industry if the two factories in Murata shut down one after another?

Guoju has issued a new round of price increase notices at the end of March, with prices of some varieties increasing by 30% to 50%. In response, a passive component channel merchant stated in an interview that in addition to Guoju, other manufacturers have also followed up on the price increase.

The above individuals further introduced the logic of price increases: from the demand side, although mobile phones have not yet seen strong demand, the demand for applications in other fields is still relatively strong, supporting the price increase of segmented products.

A source from the original factory told reporters that due to the stocking of 5G mobile phones, the downstream demand for MLCC is not expected to significantly weaken, and the epidemic may delay some orders but will not disappear. Our mobile phone customer is still urging the shipment

Many industry insiders believe that in the next step, if the epidemic in Japan and Southeast Asia worsens further, more MLCC manufacturers may enter a state of shutdown. At that time, the supply and demand relationship of MLCC will become further tense, and it is not ruled out that there may be another price increase.

It is understood that major global MLCC manufacturers include Japan's Murata Production Institute, Taiyo Yuden, KEMET, AVX, and TDK; South Korea SEMCO; Taiwan, China manufacturer Guoju, Huaxinke, etc. Among them, Guojushi accounts for about 13% and is the third largest MLCC supplier in the world.

Due to the shutdown of the three capacitor factories mentioned above due to employees being infected with the epidemic, some analysts believe that the MLCC supply in the market may be tight in the future, including Guoju and Huaxinke, which are expected to benefit from this.